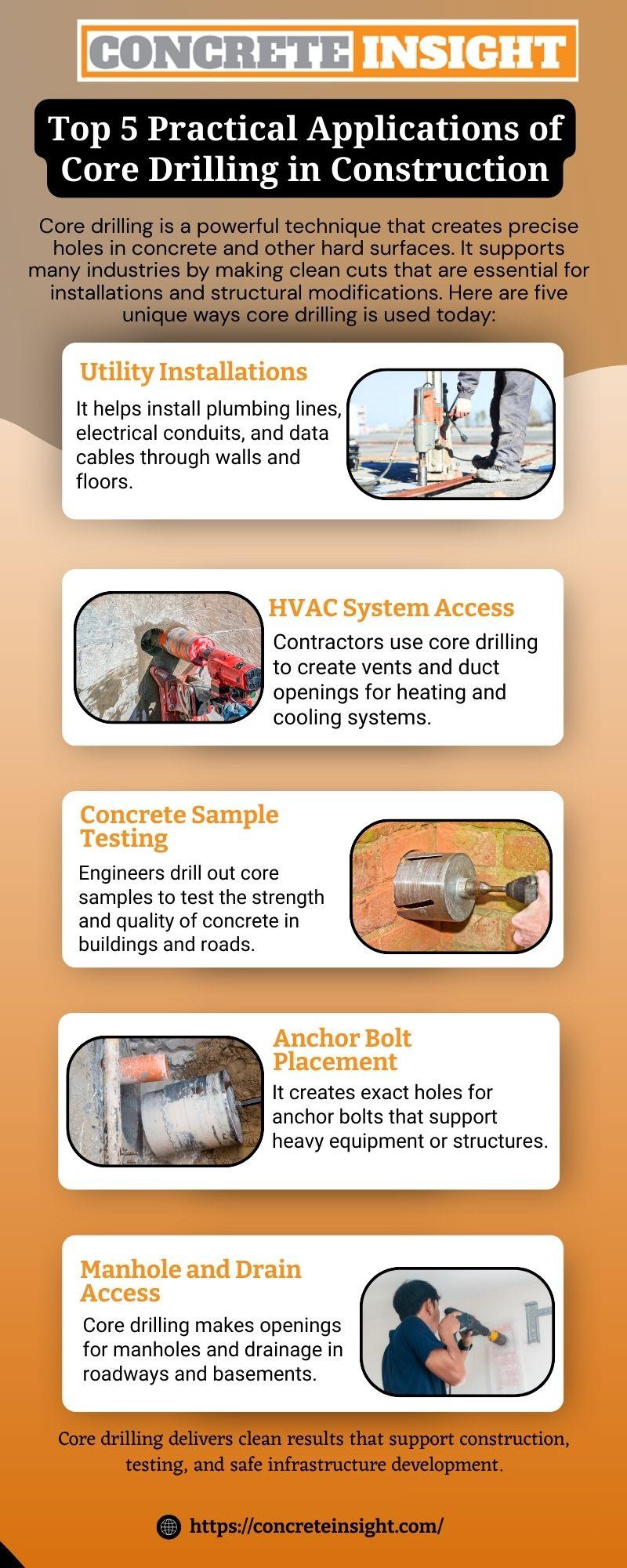

Concrete core drilling is a vital and precise method that is used to cut clean and circular holes in concrete and paved surfaces like floors and walls. This technique plays a critical role in many construction and renovation projects that involve

- Installing HVAC systems

- Running pipes

- Laying cables

Core drilling services help create neat and exact concrete and other hard materials openings. You may need these holes when you install utility lines, HVAC systems or structural anchors. This beginner's guide will explain what core drilling is and how it works. It will also describe the equipment used in the process.

What Is Core Drilling and Why Does It Matter?

Core drilling is a method that cuts round holes in hard surfaces. Unlike jackhammers that break everything around the hole, this method allows neat cuts. That is why people prefer it when they need to protect the surrounding area.

Core drilling concrete is now a common task in many projects and is commonly used in

- New buildings

- Remodeling

- Infrastructure repairs

It helps place plumbing systems and electrical wires. It also supports soil testing for engineering work. These tasks would take longer and cost more without this method.

How Core Drilling Works?

he Basics: Core drilling uses a machine that has a motor. This motor turns a hollow bit that cuts into hard surfaces. The material inside the bit comes out as a core. This creates a clear hole through the surface.

There are two ways to drill:

- Wet drilling uses water that keeps the bit cool and stops dust. People use it when working with hard materials like reinforced concrete.

- Dry drilling does not use water. People use it when water use is not allowed. It works best with soft surfaces like bricks or blocks.

The direction of the hole also matters. Workers drill vertically when they work on floors or ceilings. They drill horizontally when they need to pass through walls.

Types of Core Drilling Equipment:

Using the right tools is very important in concrete cutting and coring for good results. Here are the types of equipment often used:

- Handheld drills are small and easy to carry. They are best for small holes or drilling above your head.

- Rig-mounted drills stay fixed on a base. These are good for bigger or deeper holes.

- Hydraulic drills are very strong. They are used for heavy tasks when there is no electric power.

- Electric drills are easy to use indoors. Pneumatic drills work well in areas where there must be no spark.

Professionals choose the equipment based on the size of the job. They also check how hard the surface is and how much space they have.

Choosing the Right Core Drill Bit

The drill bit is a very important part of the process. Here is what you need to know:

- Diamond-tipped bits are the best for core drilling concrete. They are strong and last long. They can also cut through tough surfaces.

- Carbide bits are cheaper. They are good for soft surfaces like tiles or bricks. They wear out faster when used on hard surfaces.

Bit sizes can be small or large based on the hole size needed. Picking the correct bit helps avoid damage to the nearby surface. It also gives a neat cut. You should keep the bits clean and cool to make them last longer and work better.

The Core Drilling Process:

If you are new to core drilling, the steps below can help you understand how it works:

- Site Preparation and Marking: First, workers prepare the area. They clean the site and mark the exact place to drill. They also check for hidden utility lines that might cause danger.

- Setting Up the Drill Next: The drill is set up. Workers fix it in place with anchors or vacuum bases. This keeps it steady.

- Choosing the Right Speed and Pressure: The machine is adjusted based on the type of material and the size of the bit. Using too much force can break the surface. Using too little force can slow the process.

- Cooling and Dust Control: Water is used during wet drilling to keep the bit cool and control dust. In dry drilling, a vacuum is used to keep the area clean.

- Retrieving the Core Sample: After the hole is complete, the core is taken out. Sometimes, workers test this core to learn more about the surface. This is common in soil or rock testing.

Why Professional Core Drilling Services Matter You can rent the equipment and do core drilling yourself. But professionals bring experience, safety methods, and better tools. They drill clean holes without damaging the structure. They follow safety steps to keep people and property safe. Companies like Concrete Insight provide dependable core drilling services.

Final Thoughts

Core drilling looks simple but it needs the right tools and proper knowledge. It also needs attention to safety. You may want to install a pipe or an anchor. You must understand how core drilling concrete works to get the best results. This method is not only about making holes. It is about doing the job with care and accuracy.

Your work will be done safely and correctly when you work with trained professionals or use high quality tools. Core drilling is a key part of everyday construction work, even if the job is small or big.

Comments