Precision holes that preserve structural integrity are the hallmark of modern building and resource exploration, where a core drilling machine makes this possible. Whether you are planning utility penetrations, extracting material samples, or validating designs, choosing and using the right system improves accuracy, safety, and project timelines.

This guide clarifies what is a core drilling machine, its applications, wet core drilling vs dry drilling and safety best practices.

What Is A Core Drilling Machine?

At its simplest, a core drilling machine is a rotary system that cuts cylindrical samples or creates round openings by removing a “core” from a material. Most professional rigs pair a powerful motor with a stable base and a diamond core bit to deliver clean, accurate cuts in reinforced concrete, masonry, asphalt, rock, and composites.

Key Elements and Why They Matter:

- Motor and speed control: Variable RPM matches bit diameter and material hardness.

- Rig and anchoring: Vacuum base, bolt-down, or handheld stability reduces vibration and drift.

- Water delivery: Wet drilling cools the bit and suppresses dust for indoor work.

- Diamond bits: Bond hardness and segment design must match material and rebar presence.

If you are evaluating a core drilling machine for compliance and safety, the focus is on torque control, overload protection, GFCI, and dust management.

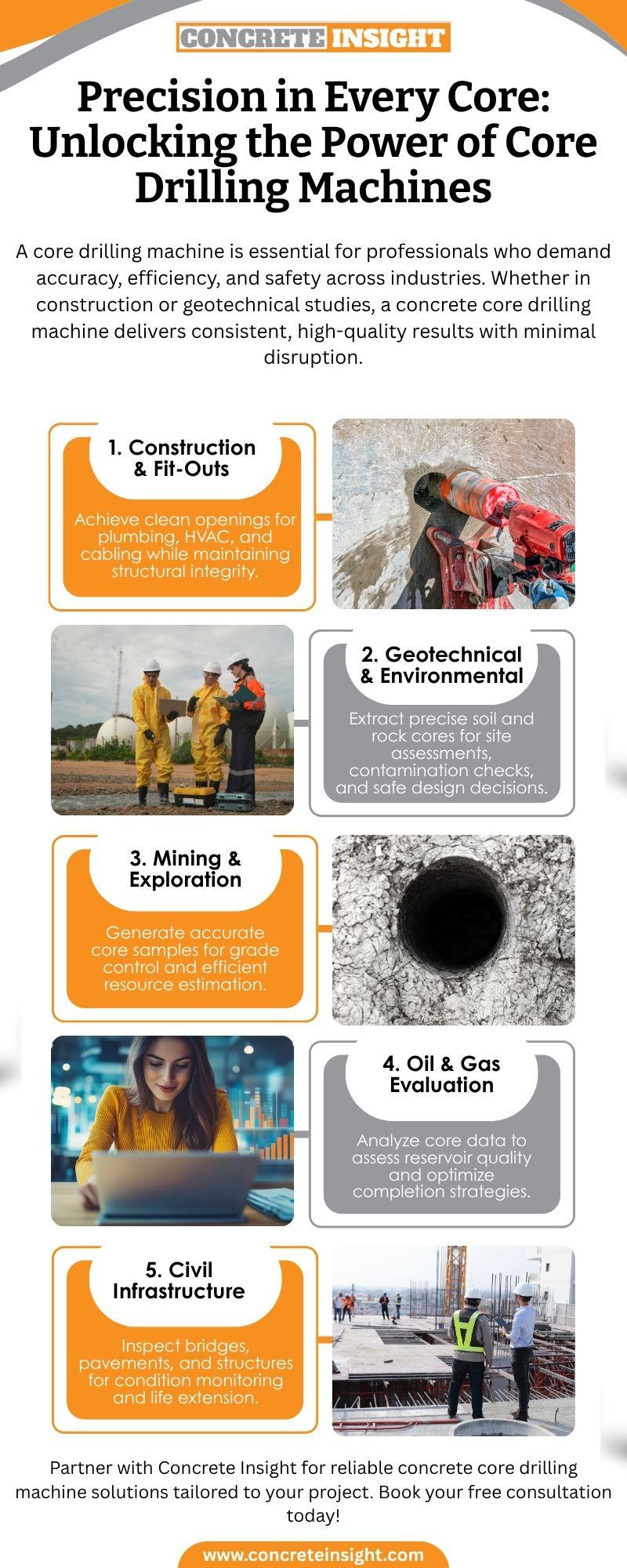

Concrete Core Drilling Machine: Industry Use Cases and Benefits

Core drilling supports multiple disciplines with measurable outcomes in quality control, risk reduction, and schedule performance.

1. Construction and Fit-Outs

A concrete core drilling machine enables precise penetrations without compromising load paths.

Use cases:- Utility sleeves for plumbing, fire protection, IT, and HVAC

- Expansion anchors and dowels

- Non-destructive material sampling for compressive strength and chloride testing

- Tight tolerances around rebar

- Minimal spalling and patching

- Faster MEP sequencing with fewer reworks

2. Geotechnical and Environmental

Cored samples provide continuous profiles of soil and rock for characterization.

Use cases:- Site investigation and bearing capacity

- Environmental monitoring wells and contaminant delineation

- High-fidelity data for design and risk assessment

- Safer foundation decisions and remediation planning

3. Mining and Mineral Exploration

Accurate core logs inform resource estimation and mine planning.

Use cases:- Grade control and structural geology

- Feasibility and economic modeling

- Better drilling targeting

- Reduced exploratory waste and cost

4. Oil and Gas Subsurface Evaluation

Oriented cores reveal reservoir quality and fracture systems.

Use cases:- Reservoir potential and permeability trends

- Completion strategy development

- Improved resource estimates

- Lower operational risk

5. Civil Infrastructure Assessment

Core samples support lifecycle extension and targeted repairs.

Use cases:- Pavement condition indexing

- Bridge deck delamination and rebar cover checks

- Data-driven maintenance planning

- Safer, longer-lasting assets

Across these sectors, a core drilling machine improves precision, reduces dust and noise when configured correctly, and accelerates schedules with fewer change orders.

Methods, Bits, And Safety Checklist for Concrete

Method and tooling choices determine speed, cleanliness, and bit life. These practical insights cover the essentials for operator guides.

Wet Core Drilling Vs Dry Drilling:

- Wet: Preferred for concrete and masonry indoors. Cools the bit, extends life, and controls silica dust.

- Dry: Useful in low-water environments or for light-duty masonry. Requires robust dust extraction and generates more heat.

Diamond Bit Selection:

- Concrete with rebar: Softer bond segments cut hard aggregates and steel more effectively.

- Green concrete or asphalt: Harder bond segments prevent glazing.

- Large diameters: Segmented turbo patterns improve debris evacuation and tracking.

Setup and Technique:

- Align and mark both faces for through-holes

- Bring RPM down as diameter increases

- Let the segments cut without excessive feed pressure

- Back off briefly when binding or hitting rebar to avoid segment loss

Safety and Compliance Checklist:

- Verify ground fault protection and tool insulation

- Use water containment and slurry management to meet silica rules

- Inspect anchors, vacuum seals, and stands for stability

- Wear eye, hearing, and cut-resistant PPE, and a respirator when dry cutting

- Lock-out and tag-out adjacent systems before penetrating walls or slabs

- Scan for rebar, PT tendons, live utilities, and embedded conduits

These practices are essential when operating a concrete core drilling machine in occupied facilities or sensitive environments.

Conclusion: Turn Designs into Clean, Compliant Cores

A core drilling machine delivers measurable gains in accuracy, safety, and schedule performance across construction, geotechnical, mining, oil and gas, and civil maintenance. Understanding what is a core drilling machine, selecting the right methods, and applying a practical safety checklist will elevate results with fewer reworks.

For expert guidance, equipment selection, and field-proven execution, partner with Concrete Insight for a concrete core drilling machine project that fits your specs, timeline, and budget.

Book your free consultation with Concrete Insight now and unlock precision coring on your next project!

FAQs

1. Why a core drilling machine used for in construction?

Creating clean, precise openings for utilities, sampling concrete for testing, and installing anchors while preserving structural integrity.

2. Is a concrete core drilling machine safe for occupied facilities?

Yes, when used with wet drilling, slurry control, and proper scanning. Wet methods cut dust and noise, and stable rigs prevent vibration and breakout.

3. How do I choose between wet and dry core drilling?

Wet drilling is the default for reinforced concrete due to cooling and dust control. Dry drilling suits light masonry when water is impractical and requires strong dust extraction.

Comments