Precision carries greater weight in concrete coring and cutting today than at any other time in the industry’s history. A 2024 trade study found that placing holes accurately can greatly reduce rework expenses. The arrival of modern core drilling machines has reshaped concrete core drilling by turning jobs that once demanded multiple passes with heavy saws into smooth, round openings completed within minutes. This guide examines everything from selecting the right machine to applying practical safety measures, helping project teams work smarter, faster, and cleaner.

Fundamentals of Concrete Coring & Cutting

Concrete coring is the practice of removing a cylindrical section from a slab, wall, or column by means of a high-speed, diamond-tipped core bit. Traditional methods, such as saw cutting or jackhammering, tend to create wider disturbance zones, whereas coring leaves cleaner edges and limits vibrations in the surrounding material.

Concrete cutting and coring often occur on the same project and serve different goals. Cutting produces straight line openings while coring focuses on precise circular penetrations that allow plumbing, wiring or structural sampling.

The Power of Modern Core Drilling Machines

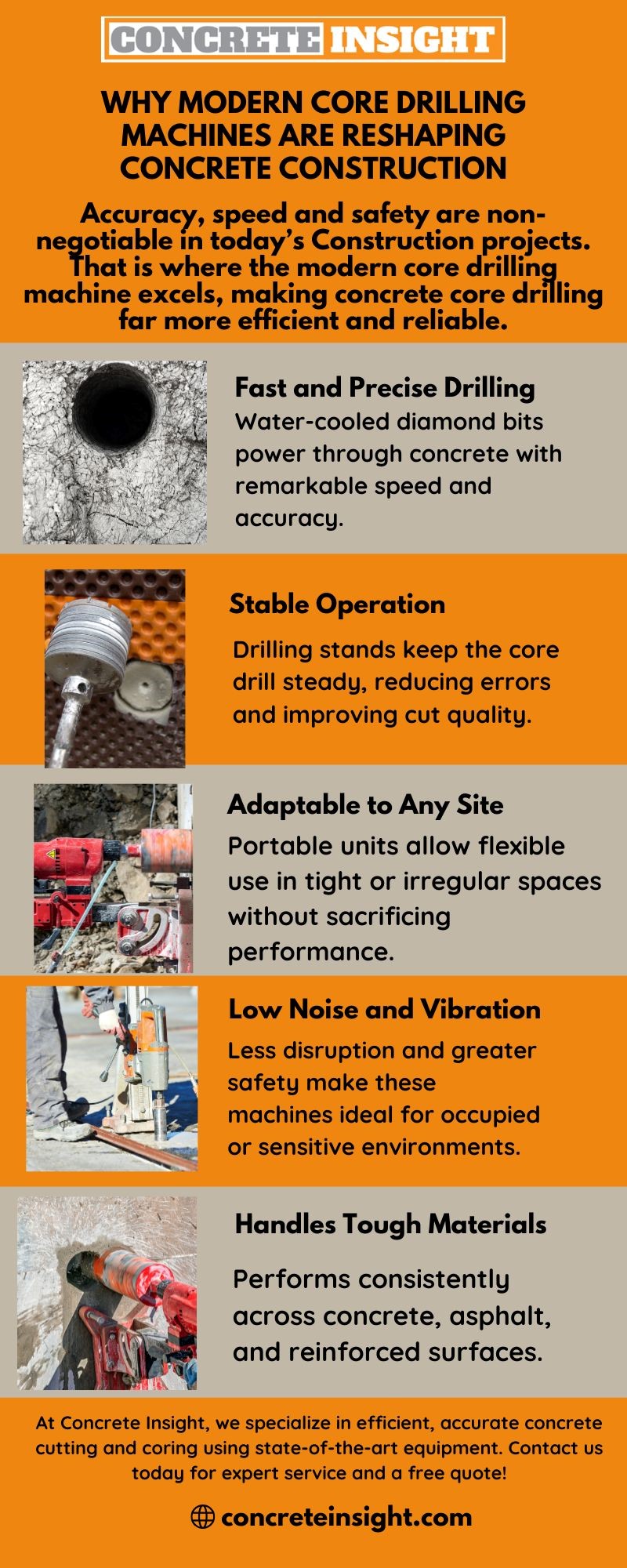

Why Modern Core Drilling Machines Stand Out

Modern machinery delivers:

- Exceptional drilling speed with water-cooled diamond bits

- Stable operation via advanced drilling stands

- Job-site flexibility thanks to portable motor units

- Lower vibration and noise for safer operator conditions

- Highly effective against versatile hard materials such as concrete, reinforced concrete and asphalt with relative ease.

These machines make concrete coring and core drilling not only more precise but also safer and quicker.

Choosing the Right Equipment: Core Drilling Machines and Tools

Types of Core Drilling Machines

Portable vs Stationary Core Drilling Machines

- Portable drills shine on smaller jobs like plumbing and HVAC penetrations.

- Stationary rigs offer more power and stability on large-scale tasks such as bridge or high-rise drilling.

Specialized Tools for Concrete Cutting and Coring

Essential tools include:

- Diamond-tipped core bits for precise holes

- Abrasive cutting wheels for straight cuts

- CNC-controlled drilling units for automated accuracy

Criteria for Equipment Selection

Power and Performance Requirements

Match tool horsepower and bit size to project needs. Thicker slabs typically demand 3–5 HP motors with 4–12 in bits, while thinner walls require less power.

Safety Features and Ergonomics

Look for machines with vibration dampening, emergency shut-offs, and lightweight handles. These reduce fatigue and improve user control.

Step‑by‑Step Guide to Concrete Core Drilling and Cutting

Pre‑Operation Planning

- Perform site assessments and mark drilling points

- Use GPR scanning to detect embedded rebar or utilities

- Gather PPE including eye protection, gloves, and hearing protection

Detailed Process Walk‑Through

1. Setting Up Your Core Drilling Machine

Secure the drill stand firmly to the surface. Confirm water supply and correct alignment for accurate drilling.

2. Executing the Drilling/Coring Process

Secure the drill stand firmly to the surface. Confirm water supply and correct alignment for accurate drilling.

3. Post‑Operation Procedures

Withdraw the bit slowly to preserve the core sample. Clean tools, check motors, and inspect drilled openings for integrity and debris.

Maximizing Efficiency and Safety in Concrete Drilling

Common Challenges and How to Overcome Them

- Rebar hits: Adjust drill angle or switch to a rebar-specific bit

- Overheating: Increase water flow and reduce drilling speed

- Power drops: Monitor amperage, replace brushes, and maintain batteries

Best Practices for Site Safety

- Conduct daily site risk assessments

- Use respirators and dust controls when needed

- Install splash guards and containment mats to protect site and workers

Cost Management & ROI

Investing in quality core drilling equipment yields:

- Up to 50% reduced labor hours

- Significant savings on project delays

- Better client satisfaction through clean, fast results

Conclusion

Concrete core drilling remains central to delivering efficient, accurate, and safe building work. Selecting a suitable core drilling machine and applying sound techniques provides speed, control, and dependable results that benefit clients and on-site crews alike. Adapting the equipment to the task at hand, combined with proven best practices, helps every opening contribute to a stronger and cleaner structure.

Whenever high-level accuracy is required, Concrete Insight offers trusted expertise in concrete cutting and coring. Our professionals bring more than 25 years of engineering and field experience to projects throughout Virginia, Maryland, DC, and neighboring regions, delivering safe and effective solutions at any scale.

Ready to move forward? Call Concrete Insight at (832) 271 to request a free quote and learn how we can turn your plans into on-site performance.

FAQs

Q1. What is the difference between concrete coring and concrete cutting?

Concrete coring drills circular holes with a diamond core bit whereas concrete cutting removes larger sections in straight lines using saw blades or abrasive grinders.

Q2. What safety precautions are essential during operation?

Teams should wear gloves, safety glasses, hearing protection and respirators. Containment measures for dust and water, along with regular equipment checks further reduce risk.

Q3. How do I decide between different types of drilling equipment?

Project scope and location guide the choice. Portable core drills suit lighter tasks or confined spaces while stationary rigs handle deeper or wider holes that require greater power and stability.

Comments