concrete coring plays a key role in the construction sector today, where the mainstream of the construction industry involves building clear paths through massive concrete slabs, which support buildings. Core drilling creates very clean and round holes without significant disruption, permitting vital electrical work and structural checks. As per any experienced person on job sites, getting this right is vital for ensuring smooth project progress.

Let's explore how Concrete Coring Services are changing the game in construction, combining traditional approaches with modern drilling equipment. We'll cover topics like checking slab depth and installing conduits effectively, all to help keep your project running well.

What Exactly Is Concrete Coring?

Basically, core drilling concrete uses a dedicated core drilling machine to cut out round sections or holes from the concrete. Instead of rough methods that break things apart, this technique gives clean results with little dust, keeping the rest of the material strong. It's like a careful operation in a field full of heavy tools.

Within the broader area of concrete services, coring is known for its flexibility. It's used in home updates, business growth projects, and factory changes. The work begins by marking the spot, such as on a floor above, and then fixing the equipment in place with secure holds for stability. A diamond-edged bit, kept cool with water to avoid getting too hot, spins at a steady pace, cutting through reinforcements and stones smoothly. Hole sizes can vary widely, from small ones for testing to larger ones for big needs. This range is what makes concrete cutting and coring so useful in diverse building tasks.

Precision Probing: Measuring Slab Thickness Like a Pro

A major strength of core drilling concrete is in checking structures, especially figuring out how thick slabs are. In building work, understanding the depth of your concrete is crucial-it's what separates a solid base from future issues. For example, when updating an older storage building, teams need to see if the original layer has stayed consistent or shifted over time. Core sampling through drilling provides that insight.

Here's a simple breakdown of the process:

- Site Prep and Setup: Clear the space and set the core drilling machine straight on the surface. For areas overhead, include safety gear like harnesses, key in this line of work.

- Drilling the Core: Start the equipment with a bit suited for the sample. Water helps keep it cool and reduces harmful dust. The bit works its way down steadily, pulling out a clean cylinder quickly.

- Extraction and Analysis: Remove the core carefully, then check it on site with basic tools for quick details. Labs can do further tests to learn more about the concrete's condition beyond just depth.

This way beats other non-invasive options that might not work well with reinforced areas, giving hands-on accuracy.

Seamless Pathways: Running Conduits Through Concrete with Finesse

Turning to utilities, which keep any building running, placing conduits for wiring, pipes, or air systems requires holes that are even, free of issues, and don't weaken the structure. Get this wrong, and you could face ongoing fixes or problems down the line. This is where Concrete Coring Services really help, turning tricky spots into easy setups.

What is the advantage of coring for these paths?

It allows for slanted or straight-up holes without the shaking from other cutting methods, which might damage edges nearby. Begin by mapping out the routes with precise tools for exact placement, which is important when dealing with sensitive lines in a tech-heavy space. The core drilling machine handles the cutting, making openings that fit your needs: smaller for basic cables, larger for bigger systems.

Think about these main steps for getting conduits ready:

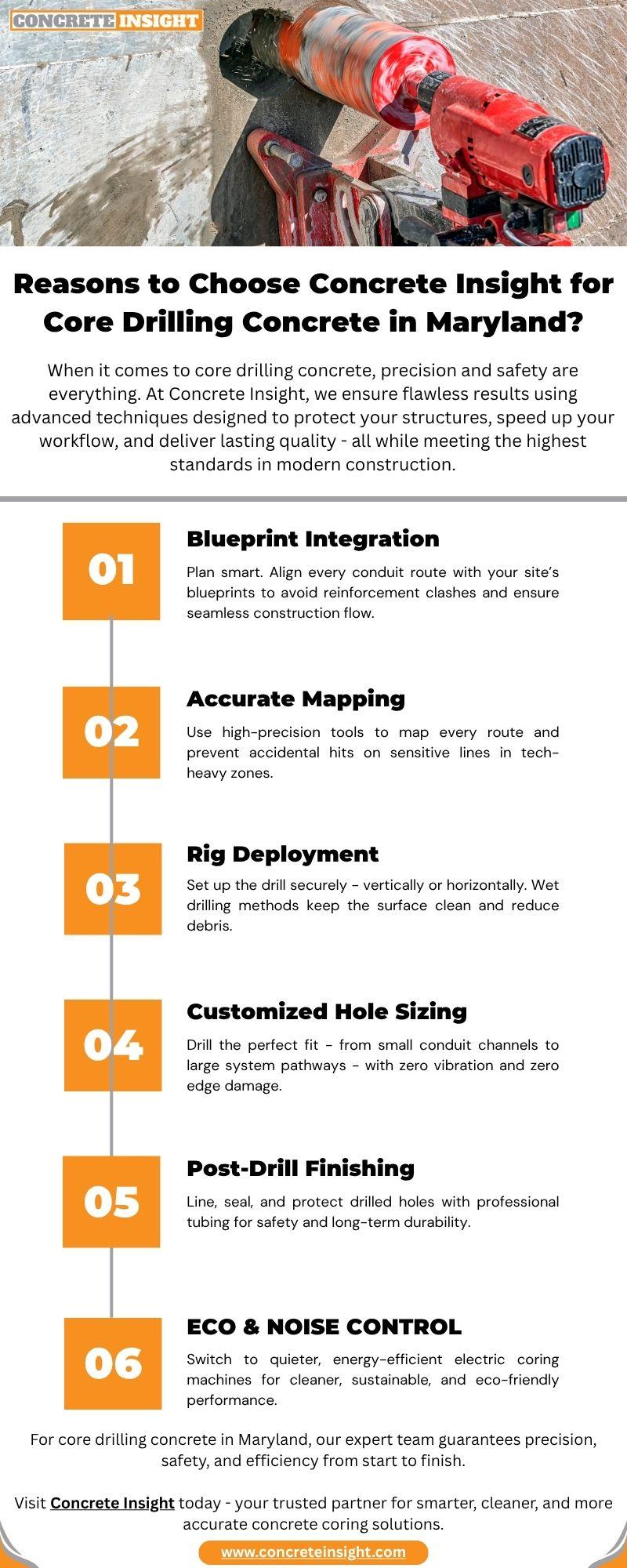

- Blueprint Integration: Match conduit plans with existing drawings, considering reinforcements through scans to avoid problems.

- Rig Deployment: Secure the drill firmly on walls for side holes, on floors for flat ones. Wet methods are ideal, clearing away bits while keeping surfaces smooth.

- Post-Drill Finishing: Line the hole with protective tubes, seal it properly, and add safety features if required for taller buildings.

In busy city projects, this accuracy speeds up the overall work, based on insights from groups like the Concrete Sawing & Drilling Association. It's particularly helpful in areas prone to movement, where holes need to work with flexible parts to handle shifts without breaking connections. For teams focused on the environment? Quieter electric machines are becoming popular, reducing impact while providing strong performance.

Tools of the Trade: Cutting-Edge Gear That Drives Results

Talking about coring wouldn't be complete without looking at the equipment. Modern core drilling machine options include motors that adjust speeds easily, handling different types of concrete. Diamond parts, enhanced with special materials, hold up well over time.

Safety is built in everywhere: features that stop the machine if things get unsteady, and systems to control dust that follow health rules. For those in concrete cutting and coring, it's this mix of power and smart design that turns tough requirements into routine achievements-whether working through thick walls or testing special slabs.

Final Thoughts:

From revealing details about slabs to creating reliable paths for conduits, concrete coring is more than a step-it's a smart choice that leads to better outcomes in demanding projects. As construction evolves toward more efficient and sustainable practices, using solid methods like these helps you not only follow rules but go beyond what's expected.

If you're handling a job in the DMV region and want skilled help for top-notch core drilling concrete, reaching out to an experienced core drilling company Maryland can be a game-changer. Check in with experts like those at Concrete Insight we offer deep knowledge and support your plan. What's your next coring task? Let's tackle it head-on.

Comments