In modern construction and renovation, concrete coring is an essential construction technique. The Concrete Core Drills Market was valued at approximately USD 450 million in 2024 and is forecast to reach about USD 670 million by 2033, growing at a compound annual growth rate (CAGR) of around 5.1% from 2026 to 2033. Precise holes in the slab and wall are a crucial part of processes like installing plumbing, electrical piping or HVAC systems. This technique often comes with challenges that can slow down progress, raise costs, and affect the quality of the final work.

For better safety and efficiency, every contractor must master troubleshooting the core drilling problems. This blog covers common challenges and their solution for best results.

Understanding Concrete Core Drilling

Concrete core drilling technique is used to create cylindrical holes in the concrete structure using diamond tipped core drill bits to cut through hard materials like reinforced concrete, masonry, and stone. This process offers precision as compared to traditional methods. Drilling holes in the slab and wall surfaces has difficulties that can arise from the material characteristics, equipment issues and environmental factors.

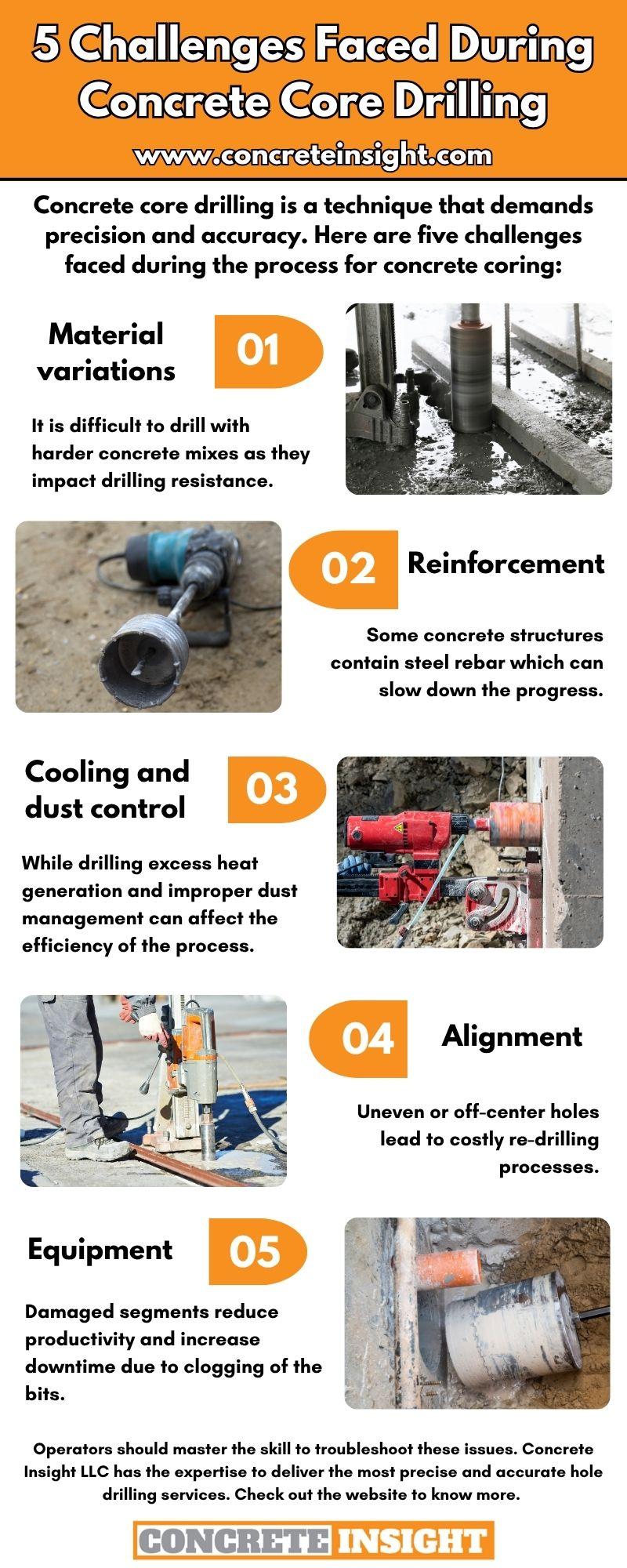

Key challenges include:

- Material: Different concrete mixes, aggregate sizes and curing stages impact drilling resistance. It is difficult to drill with harder material.

- Reinforcement: Some concrete structures contain steel rebar, mesh or embedded objects that can damage drill bits. These reinforcements can slow down the progress.

- Cooling and dust control: While drilling excess heat generation risks damaging equipment. Improper dust management can affect the health and the efficiency of the process.

- Alignment: Uneven or off-center holes lead to installation problems. These poor-quality holes can cause costly re-drilling.

- Equipment: Core bits can get stuck due to clogging from debris. Damaged segments reduce productivity and increase downtime.

Overheating Drill Bits and Equipment

One of the most common issues during concrete coring and core drilling is overheating. Core bits can generate heat due to friction against hard surfaces. This heat can quickly degrade diamond segments or cause motor failure which can lead to costly replacements and project delays.

Causes:

- Continuous drilling without breaks

- Insufficient water flow for cooling

- Blocked water supply lines or nozzles

- High drilling speed is inappropriate for the concrete hardness

Solutions:

- Maintain a steady water flow: Water serves as a coolant and lubricant throughout the process. Ensure that hoses, pumps, and drill nozzles are clear of blockages to maintain a steady water supply to the drilling site.

- Regular breaks: Stop drilling periodically to let the drill bit and equipment cool down. This also allows debris to clear in order to prevent additional friction.

- Monitor drilling speed: Adjust drilling speed according to the density of the concrete structure. Slow speed reduces heat generation when drilling through dense materials or rebar.

- Equipment checks: Inspect the drill apparatus regularly to avoid any damage. Replace the faulty parts immediately.

Managing Alignment and Producing Quality Holes

Misaligned or uneven holes can lead to installation issues or structural weaknesses. Achieving perfectly round and accurate holes can get difficult whether drilling for pipes, electrical conduits or inspection holes.

Causes:

- Improper drill rig setup or unstable mounting

- Operator hand drills are lacking steady guidance

- Vibrations or movement during drilling

- Incorrect pressure application on the drill

Solutions:

- Use a stable drill rig: Fix the drill securely to avoid movement or vibration during operation. Professional-grade rigs offer guiding plates to maintain a consistent angle.

- Opting for templates: Using steel guide plates increases precision for drilling holes in walls or slabs. It helps in maintaining the same angle and alignment.

- Consistent pressure: Applying appropriate pressure downwards makes sure that the drill bit cuts without wobbling. Too much or too little pressure can cause uneven holes or damage the bit.

- Pre-check hole locations: Carefully measure and mark the slab or wall surfaces before coring to reduce errors. This can offer precision and match the requirements of the project without any fail.

Dealing with Rebar and Unexpected Obstructions

Concrete slab and wall reinforcement through steel rebar or mesh causes frequent obstacles during core drilling. Hitting rebar without warning can increase the risk of damaging the core bit and jamming the drill. Hidden debris or embedded materials can complicate hole creation as well.

Causes:

- Hard steel damaging diamond segments

- Increased drilling resistance causes jams or overheating

- Sudden drill bit deflection changing hole alignment

- Debris accumulation is impairing drill progress

Solutions:

- Assess when hitting rebar: Do not force through the rebar. Pause the drilling to evaluate whether the bit or equipment shows signs of damage.

- Switch to appropriate bits: Use core drill bits specifically designed for reinforced concrete. Some bits have carbide edges which are ideal for cutting steel.

- Adjust drilling angle carefully: Shift slightly to avoid heavy reinforcement clusters while maintaining hole specifications. Minor repositioning can deliver precision and ease while drilling.

- Clear debris promptly: Remove residue of rebar or concrete using brushes or water to prevent jamming. Maintain segment cutting edges for cleaner holes.

- Slower speeds and increased water flow: These reduce friction and prevent overheating. With slow speed and appropriate water flow you can extend bit life while cutting steel rebar.

Preventing and Clearing Jams, Managing Dust and Debris

The whole process produces rock dust and slurry debris that must be managed properly to avoid equipment jams, dust inhalation risks and surface contamination.

Causes:

- Applying excessive pressure and drilling speed

- Inadequate water flow for cooling and cleaning the debris

- Not wearing proper safety clothes

- Choosing an incorrect drill bit leads to core buildup

Solutions:

- Flush continuously with water: Water flow flushes dust and core cuttings away from the hole to prevent buildup around the bit that can cause jamming of the equipment.

- Use dust extraction systems: Vacuums reduce airborne dust particles, improving safety and workspace cleanliness in confined spaces.

- Use alternating drilling movements: Try alternate clockwise and counterclockwise rotations gently to free the jammed bit without causing shaft damage.

- Regular bit and equipment cleaning: Clean diamond segments and other metal components to avoid debris buildup after every hole or every few minutes of the process.

- Wear appropriate PPE: Operators should use masks, goggles and protective clothing to avoid dust inhalation and eye injury.

Conclusion

Core drilling is a technique that demands precision and care. Troubleshooting effectively is necessary when working with challenging slab and wall conditions. From controlling overheating and maintaining hole alignment to managing rebar obstructions and preventing core bit jams, operators must master this skill.

What if you get expert guidance and concrete core drilling services from the best service provider? Concrete Insight LLC delivers the most precise and accurate hole drilling services at an affordable price with special discounts. With our years of experience, we offer premier services to streamline your plumbing, electrical and HVAC system installation processes. Check out our website to know more.

FAQs

- Will the core drilling procedure harm my concrete structure or generate undesirable vibrations?

No, professional core drilling employs specialized bits with diamond tips and accurate methods to create clean holes without inducing cracks or structural harm. - Is dust, noise, and slurry controlled during concrete core drilling to minimize effects on my site?

Yes. Reliable service providers implement ongoing water flushing, dust extraction systems and noise mitigation techniques to manage dust and slurry for a cleaner and safer workplace. - Is it possible to perform core drilling in confined or difficult to access areas on my property?

Yes. Professional firms utilize specialized compact core drilling rigs operated by trained personnel to efficiently create accurate holes in tight spaces while minimizing unintended damage.

Comments