Concrete is the most popular construction material in the world. Did you know that the global concrete market size was estimated at USD 1.82 trillion in 2024 and is projected to reach USD 2.28 trillion by 2030 ? Concrete core drilling is a technique used to create precise and circular holes in concrete during construction. This technique offers multiple benefits. Sometimes, when faced with demanding sites such as tight spaces, high-rise buildings, or confined rooms, core drilling can get hard.

Even though some sites can get challenging, there are still solutions for core drilling and getting the job done. This blog will cover the solutions to the difficulties faced at the construction site for better concrete core drilling.

How Does Concrete Core Drilling Work?

Concrete core drilling uses a rotating ring-shaped drill bit, which is often tipped with industrial diamonds or carbides to cut a cylindrical hole in concrete. The bit, which is mounted on a drilling machine, is pressed against the concrete and rotated, grinding away the material to create a core sample and a cylindrical hole. These diamond-tipped bits can range from a few millimeters to several feet in diameter.

This is crucial for construction projects like retrofitting and installing plumbing, electrical, and HVAC systems. It offers benefits like:

- Precision: Advanced equipment which is used in concrete core drilling ensures perfectly round holes with specific diameters. This perfection is necessary for tasks like utility and anchor installations.

- Minimal disruption: This technique causes minimal disruption like dust, noise pollution, and vibrations, which makes it suitable for occupied buildings.

- Clean edges: With precision, it gives clean edges, which enhance the overall look of the project.

Challenges Faced at Construction Sites During Core Drilling.

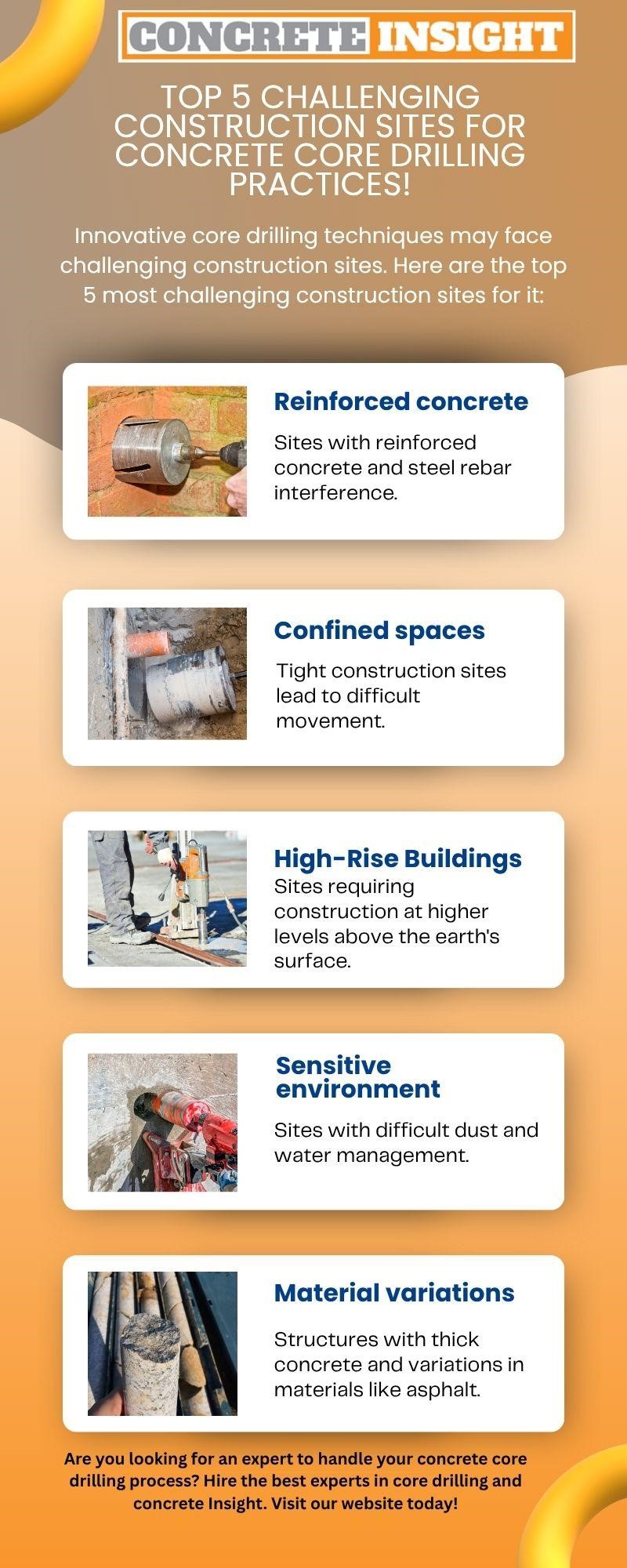

Concrete core drilling is a precision-focused process that uses advanced equipment. But sometimes, the construction site can be demanding. Here are top five most demanding sites for concrete core drilling:

- Reinforced concrete: Sites with reinforced concrete and steel rebar interference can cause difficulty due to the hardness and density of the steel.

- Confined spaces: Tight construction sites lead to hard time in the maneuverability of workers, which can further lead to safety concerns and property damage as well.

- High-Rise Buildings: When core drilling is required at a high-rise building, it leads to safety concerns for the workers requiring specialized equipment as well.

- Sensitive environment: The sites where dust and water management can get difficult due to the sensitivity of the environment.

- Material variations: Drilling through thick concrete and other dense materials, like asphalt, can cause obstacles in drilling.

Solutions to These Challenging Sites

Challenging conditions don’t require you to compromise on precision. There are solutions figured out by experts for core drilling at testing sites.

Solutions to Reinforced concrete:

- Using diamond-tipped core bits, which are specifically designed to cut through both concrete and steel reinforcement.

- Pre-scanning with rebar detectors with the help of ground-penetrating radar (GPR) or rebar locators can help you map out the rebar positions to avoid or prepare for them.

- Adjusting the drilling speed and pressure when hitting the rebar will reduce heat and damage on the bit.

- Make sure continuous water flows to cool the bit and flush away debris.

Solutions to Confined spaces:

- Using handheld and compact drills offers flexibility and maneuverability in confined areas where larger drilling equipment cannot reach.

- Angle drilling is a better option when it comes to core drilling in tight spaces, as this technique requires the core drilling machine to be positioned at a certain angle relative to the surface to be drilled.

- Training the workers in confined space entry and ensuring they use appropriate personal protective equipment.

- Make sure there is proper airflow and ventilation during the procedure.

Solutions to High-Rise Buildings

- Using lightweight, portable drilling equipment for easier transportation and set up at height.

- Installing guardrails and fall protection while ensuring all workers are equipped with harnesses as well.

- Using catch platforms to safely manage falling debris.

- Scheduling work in coordination with the building management to minimize disruption.

Solutions to Sensitive Environment

- Using wet drilling techniques will minimize dust with the help of water to suppress particles at the source.

- Using specialized vacuums that can collect both dust and water prevents contamination.

- Use plastic sheeting or temporary barriers to seal off work areas to contain dust and water.

- Scheduling work during off-hours to reduce exposure to sensitive operations.

Solutions to Material variations

- Matching the bit type and size to the specific material being drilled.

- Modifying speed rate, feed rate, and pressure based on material density.

- Ensuring your equipment has adequate power for thick or dense materials,

- Checking and replacing bits as needed to maintain efficiency and safety.

Core drilling has numerous applications in the construction industry. It is used for utility installation, anchor installation, material testing, mining, renovation, remodeling, and many more. This innovative technique may face difficulties that require innovative solutions.

Final Thoughts

Now you know the solutions to the challenging construction sites that you may face during the process of concrete core drilling. You can successfully navigate through the obstacles with the help of these solutions and an expert who has adequate knowledge of them. Do not try to drill a hole all by yourself.

If you are looking for an upgrade to your construction with concrete core drilling, you must check out the experts in this field: Concrete Insights. We combine our knowledge and years of experience to provide you with the best core drilling services in a hassle-free and well-structured manner. Get in touch with us today!

FAQs

1. What is concrete core drilling?

Concrete core drilling is a technique in which a cylindrical hole is drilled into the concrete structures with the help of a rotating ring-shaped drill bit. Often, these bits are tipped with industrial diamonds to cut a cylindrical hole in the concrete.

2. Why is core drilling used?

Core drilling is used to drill a hole in concrete structures for various reasons, such as plumbing, electrical utilities, and installing HVAC systems. It gives clean and precise holes for the construction process

3. What are the most challenging sites for concrete core drilling?

Sites like tight spaces, high-rise buildings, and reinforced concrete and steel rebar are the most challenging sites when it comes to concrete core drilling.

Comments