In building and remodeling any kind of work, detail matters and achieving precision is what makes it or breaks it. Concrete coring services come in handy when you need to scoop a clean cut and round hole through a concrete slab that has a lot of thickness to accommodate such things as pipes or cables. This is a sound and reliable approach, particularly when the task of the job becomes larger and more complex, such as in urban towers or large refurbishment of facilities.

Strict rules will keep everything safe, long-lasting and well-put-together. Then what does it take to deliver core drilling concrete that complies with ASTM regulations and time-tested methods of doing things in the field? Let's get into it.

What Exactly Is Concrete Coring, and Why Does It Matter?

Coring of concrete is done with a special drill that can make round holes in concrete with minimal disturbance, which is appropriate in case of delicate places. It can be accomplished by measuring the concrete and cutting it with a diamond bit, frequently with water to keep the dust down. The holes may be as small as 1 up to 60 inches. ASTM standards make it easier to handle the problem and reduce the cracks in future.

The Power of ASTM Standards in Core Drilling Concrete

ASTM sets the bar high for testing materials, and in core drilling concrete , you can't skip their guidelines. For example, ASTM C805 deals with hammer tests on hard concrete, often done alongside Coring to confirm how strong it is. By doing this, workers steer clear of uneven samples that might lead to wrong strength readings and extra costs for fixes.

On top of that, industry habits from groups like the Concrete Sawing & Drilling Association (CSDA) stress trained people and tuned-up tools. A good core drill needs steady power to keep the bit straight, making sure holes are level and accurate. Just this year, in 2024, CSDA updated tips on handling water in wet Coring, cutting down on wastewater by about 30% in city areas-it's a smart way to be kinder to the environment while keeping things moving.

What does this mean for your work? When Coring follows these rules, you deal with fewer fixes later. A hole that's off could hold up air system setups for days and bump up expenses. With services that match ASTM, you're not just making openings-you're setting up for the long haul.

Essential Equipment: Choosing the Right Core Drilling Machine

You can't do good work without the right tools, and the core drilling machine is the main one here. They've come a long way from bulky setups to easy-to-handle models. Wet drills use water for deep cuts in strong concrete, while dry ones are better where dust is a big no-no, like in computer rooms.

Things to watch for:

- Diamond-impregnated bits: Rated for toughness, like A9 types for hard mixes, so they handle steel bars easily.

- Variable speed controls: You can change speeds from 300 to 1,500 turns per minute, matching the job's depth for best results.

- Rig stability: Bases that suck down or bolt in to stay put, especially on ceiling jobs.

A solid Concrete Core Drills system can punch a 12-inch hole through two feet of concrete in less than 10 minutes, quicker than grabbing a snack. Add laser guides, and you get spot-on accuracy, turning tricky tasks into routine ones.

Real-World Applications: Where Concrete Coring Services Shine

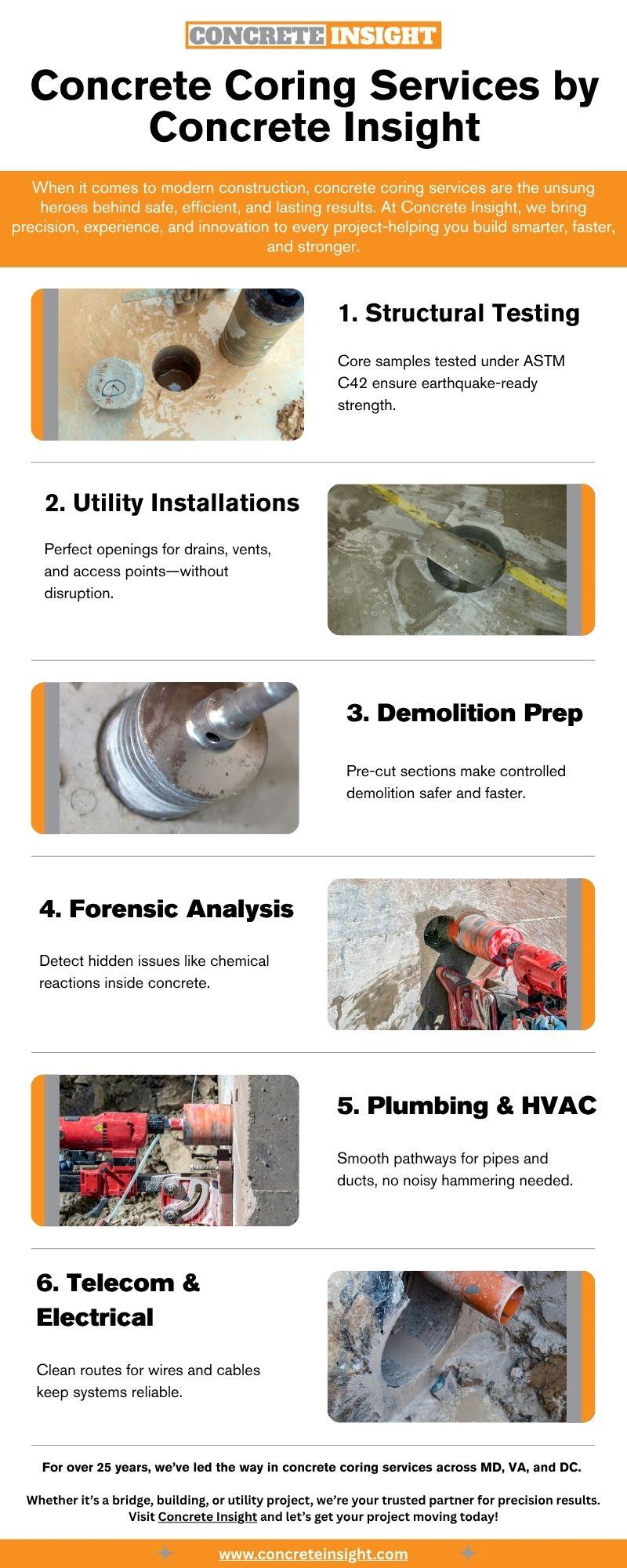

You'll see concrete coring services in all sorts of spots, from fixing old bridges to kitting out new tall buildings. For plumbing, bigger cores let drain pipes through without hurting the slab's strength. Electricians use them for wire paths, running lines through without a trace.

Take heating and cooling updates: One core drilling concrete task can guide big air tubes up high, skipping noisy hammering. In phone and internet work, clean routes are key for good signals; core making that happen reliably.

Quick list of common spots:

- Structural Testing: Pull full cores under ASTM C42 to test real strength, crucial for earthquake-proofing.

- Utility Installations: For access points, drains, and vents with little stoppage.

- Demolition Prep: Planned cores make sections easier to break safely.

- Forensic Analysis: After issues, samples show hidden problems like chemical reactions in the mix.

These are everyday needs, not rare ones. With more focus on eco-friendly building, Coring's gentle approach fits right in with credits for low-impact methods.

Navigating Challenges: Best Practices for Flawless Execution

Even experienced folks run into issues, like tangled steel, bumpy spots, or heat changes. The fix? Good planning up front. Here are some best practices to follow:

- Use radar scans to spot steel layouts and avoid surprises while drilling.

- Wet methods keep dust within safe limits set by work rules (under 5 mg/m³ for breathable bits), and special vacuums grab what's left.

- Put safety up front: Wear full gear like masks, gloves, and straps for high-up work.

- Check vibrations to stay under 5 m/s², so hands don't get sore over time. For the planet? Systems that reuse water cut down on mess.

- Handy advice: Do it when the site's quiet. A smart concrete cutting and coring run run can finish early, letting everything else roll on.

What's Next for Core Drills?

Things are moving fast with new ideas. Robot core drilling machines now adjust to rough floors, speeding up by 40%. Battery Concrete Core Drills mean no cords in cramped areas. Sensors that watch wear can warn you ahead, saving time.

Green options are big: Reused diamonds make bits last longer, and natural coolants swap out rough stuff. By next year, 2025, look for mixed power rigs that use 25% less energy per task.

Wrapping It Up

That's the rundown on concrete coring services that go beyond just meeting ASTM standards and standard industry ways. From the spin of the core drill to the relief of a perfect fit, it's about mixing tools, skills, and care for outcomes that stick around.

Thinking about a job? If you're around MD, VA, or DC and want folks with more than 25 years under their belt, reaching out to pros like Concrete Insight might be worth it. In the tough world of concrete, getting it right isn't extra-it's what gives you the upper hand. Got a project in mind? Share it and see what clicks.

Comments