In modern construction, precision is not a luxury, it is a safeguard. Industry analyses indicate that cutting and drilling mistakes can account for more than 70 percent of total rework costs on complex projects which is a major hit to both schedules and budgets. Accurate concrete coring and carefully planned concrete cutting and coring methods significantly reduce those costly surprises.

Concrete coring allows builders, engineers and facility owners to create clean, measured openings through tough structural elements while protecting safety and performance. Combined with professional concrete core drilling and scanning, it turns every project into a predictable, well controlled operation.

What is Concrete Coring

Concrete coring is the process of using a diamond-tipped cylindrical bit to drill smooth, circular holes through concrete, masonry, or stone. Those openings can range from small penetrations for cables to large cores for ducts, plumbing, or testing.

Concrete coring plays a central role in:

- Creating pathways for mechanical, electrical, and plumbing (MEP) services

- Installing HVAC ducts, fire protection lines, and communication systems

- Extracting samples for structural and material testing

- Retrofitting older structures to suit new occupancies or codes

Instead of breaking or hammering the concrete, professionals remove a clean cylinder, protect critical reinforcement and maintain the integrity of slabs, beams, and walls.

How Concrete Coring Works

At a basic level, a rotating diamond core bit, steady pressure, and cooling water combine to grind through concrete and aggregate. Behind that simple idea sits careful planning and a clear process.

Experienced teams in concrete core drilling typically:

- Review structural drawings and existing utility layouts.

- Scan the concrete to locate rebar, post-tension cables, and embedded services.

- Mark safe drilling locations and required core sizes.

- Set up a stable core drilling machine to control alignment and depth.

- Manage slurry or dust to maintain a safe and tidy workspace.

What Type of Equipment is Used in Concrete Coring?

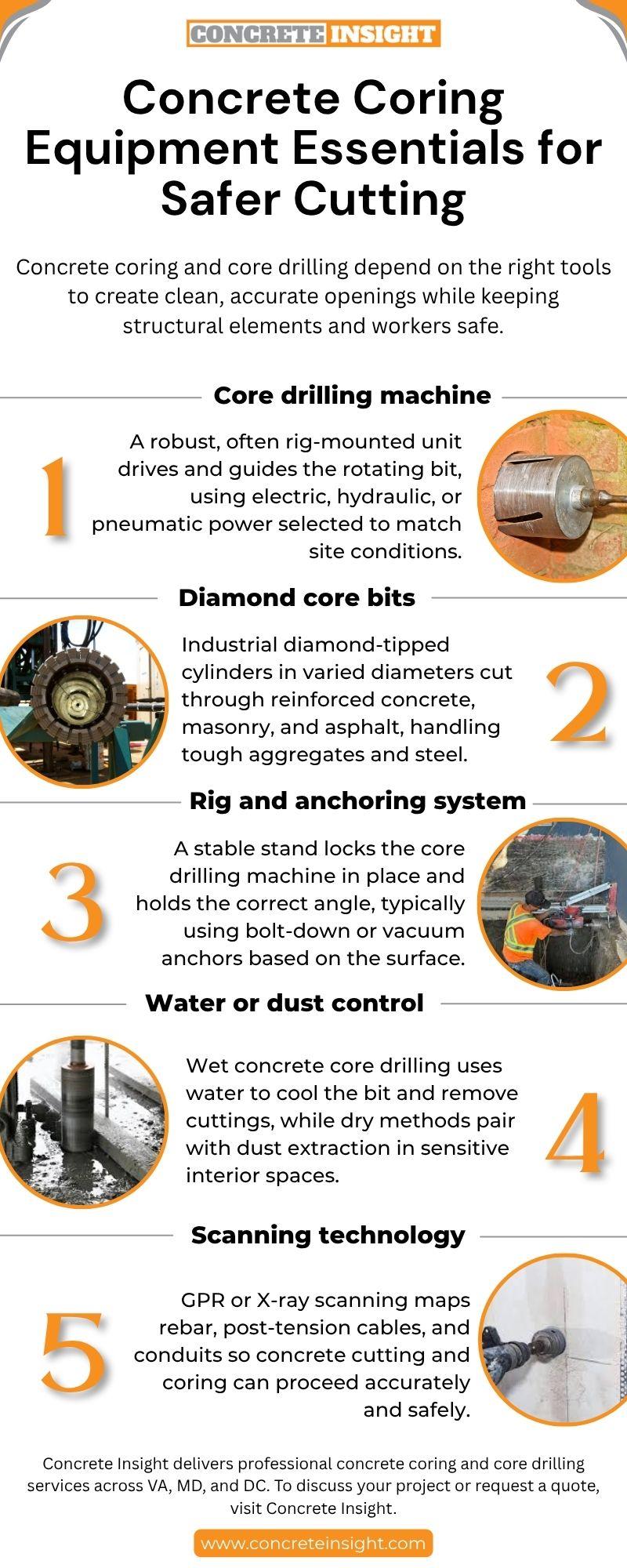

Modern concrete coring depends on specialized tools that balance power, control, and operator safety. Key equipment includes:

Core Drilling Machine

A heavy-duty, often rig-mounted unit that powers and guides the rotating bit. Machines may be electric, hydraulic, or pneumatic, selected to suit site constraints and power availability.

Diamond Core Bits

Cylindrical bits embedded with industrial diamonds, available in many diameters and lengths. Different segments are designed for reinforced concrete, masonry, or asphalt and are capable of cutting through tough aggregates and steel.

Rig and Anchoring System

A stand or rig holds the core drilling machine firmly in place and maintains the correct angle. It may be bolted to the slab or attached using a vacuum base, depending on the surface.

Water Supply or Dust Collection

Wet concrete core drilling uses water to cool the bit and carry away cuttings, which helps the bit last longer and improves cut quality. In sensitive interiors, dry coring with proper dust extraction might be chosen instead.

Scanning Equipment

Many professional concrete cutting and coring crews use GPR scanning or X-ray systems to map reinforcement and utilities before any cut is made.

Choosing the right combination of core drilling machine, bit and scanning approach is one reason professional concrete core drilling contractors achieve consistent, safe results far more often than ad hoc site crews.

What Makes Concrete Coring Unique?

Concrete coring delivers several advantages compared with more aggressive methods like jackhammering or random breaking.

High Precision

The method produces a round, accurately sized opening that matches design requirements. That accuracy matters for pipe alignment, firestopping, acoustic performance, and even visual finish.

Lower Structural Impact

Instead of shattering the concrete around the penetration, the core is removed in one solid piece. Microcracking and damage in the surrounding area are reduced, which supports long-term durability.

Protection of Rebar and Tendons

When GPR scanning before coring is used, technicians can position openings to avoid critical rebar cages and post-tension tendons, lowering safety and repair risks.

Versatility in Difficult Spaces

Core drilling can be carried out in floors, walls, ceilings, and at angles. That flexibility suits complex retrofit work, congested plant rooms, and tight urban sites.

Key Takeaways

- Concrete coring delivers precise circular openings for MEP services, testing, and retrofit work while protecting the surrounding structure.

- Pre-planning with drawings and GPR scanning greatly reduces the risk of striking rebar, post-tension cables, or hidden utilities.

- A well-set core drilling machine, quality diamond bits, and a stable rig are central to accurate, clean holes.

- Choosing between wet and dry core drilling, plus proper slurry or dust control, supports safer, more efficient sites.

- Specialist concrete cutting and coring teams follow a clear procedure that cuts down rework, noise, and on-site risk.

The Concrete Core Drilling Procedure: How Professionals Approach Coring Projects?

A disciplined workflow helps specialists deliver predictable results on every coring project. A typical concrete core drilling procedure involves several stages:

1. Initial Assessment and Planning

The project team reviews drawings, site constraints, and performance requirements. Core diameters, depths, and locations are decided while structural and safety considerations are evaluated.

2. Scanning and Layout

Technicians scan the concrete for rebar, conduits, and post-tension cables, then mark safe zones and exclusion areas. Color codes and clear symbols help everyone on site understand the plan.

3. Rig Setup and Alignment

The core drilling machine is positioned, anchored, and aligned to the required angle and exit point. Precise setup here prevents misaligned penetrations and rework.

4. Active Drilling

The operator begins cutting, adjusting feed rate, water flow, and rotation speed as the bit moves through aggregates and any mild reinforcement. Skilled operators listen to the machine and feel changes in resistance.

5. Core Removal and Cleanup

After the hole is complete, the concrete core is removed. In some cases it is labeled for compressive strength or petrographic testing. Slurry or dust is collected, and the work area is left clean and safe.

6. Finishing and Follow-On Work

Edges may be smoothed, sleeves installed, or firestopping materials applied around the opening. Many teams also coordinate follow-up tasks such as concrete core drilling for plumbing lines or cable trays.

Conclusion

Concrete coring has evolved into a core component of safe, efficient construction and renovation. From creating accurate openings for MEP services to delivering reliable test samples, concrete core drilling gives project teams control over some of the most delicate tasks on site.

Concrete Insight, based in Reston, Virginia and serving VA, MD, and DC, combines professional engineering knowledge with field experience in concrete GPR scanning, concrete coring, and testing. Builders and owners who value precision and safety turn to Concrete Insight to handle concrete cutting and coring with confidence.

To begin, call Concrete Insight at (571) 236-8522 or visit our website to request a free quote.

FAQs

1. What is concrete coring used for in buildings?

Concrete coring creates accurate circular openings in slabs, walls and beams for pipes, cables, ducts, anchors and structural test samples while keeping the surrounding concrete and rebar largely intact.

2. How much does concrete core drilling cost per hole?

The cost per hole for concrete core drilling depends mainly on diameter, depth, access and reinforcement so most projects benefit from a site specific quote from a specialist coring contractor.

3. Do projects really need GPR scanning before concrete coring?

GPR scanning before concrete coring helps locate rebar, post-tension tendons and hidden utilities which significantly lowers safety risks and unexpected repair costs.

4. How long does a typical concrete coring job take?

Duration depends on hole size, depth, reinforcement, and access, but many standard concrete coring and core drilling tasks take from a few minutes to under an hour per hole on a well-prepared site.

5. What is the difference between concrete coring and traditional drilling?

Concrete coring uses a diamond core bit to cut clean, round openings with less vibration and damage, while traditional impact drilling tends to chip and crack the surrounding concrete, which makes it less suitable for structural or precision work.

Comments