The world that we surround ourselves with is made of concrete, the floor we walk on, and the bridge we drive over. However, there are occasions when it is necessary to alter such solid material to meet new requirements, such as putting pipes in it or even testing its integrity. That's exactly what concrete cutting and coring handle, and they do it with real skill. Concrete drillers employ these tricks on a daily basis so as to make spaces work harder without their heads aching. We are going to take a tour of what these processes entail today, how they are done, what equipment is used, and how they are applied in real work. Continue reading, and you will understand the reason why they are such a phenomenon in construction.

What is Concrete Cutting and Coring?

Concrete cutting and coring basically means making exact changes to concrete so it suits what you need. Cutting is about slicing through things like walls or floors to open up space or fix issues. Coring takes it further by drilling round holes with a core drill to pull out samples or run lines for water or wires. You see this stuff in new builds and old fixes alike. Need to snake in some ducts or test if the slab's tough enough? Concrete drilling companies step in with methods that keep everything steady. Lately, with more cities growing fast, the market for this work is picking up steam-experts say it'll keep climbing through 2025 thanks to all the road and building projects popping up.Methods of Concrete Cutting and Coring

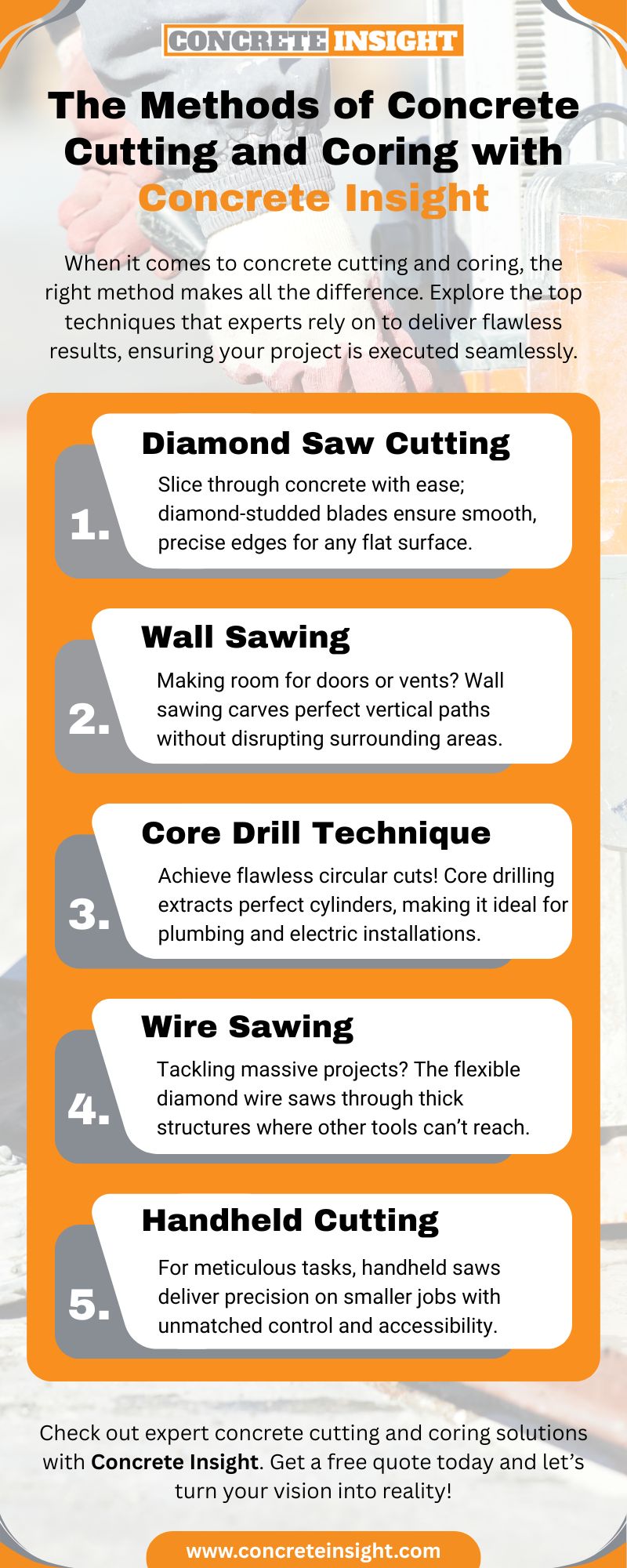

When it comes to concrete cutting and coring , there's no one-size-fits-all. Each job calls for its own approach, picked based on the setup and what's at stake. Let me run through the main ones that pros swear by.Diamond Saw Cutting

Diamond saws lead the pack here, with blades studded in tough diamonds that chew through concrete smooth as silk. They're great for flat jobs, like scoring lines in a driveway or trimming off bad spots on a patio. You get straight edges and hardly any shake, which keeps the rest of the build happy.Wall Sawing

Got a wall that needs a big door or vent? Wall sawing's your friend. It uses a diamond blade on a rail to carve vertical paths without messing up the area around it. We've watched crews pull this off in tight spots, like adding windows to an old warehouse, and it's always spot-on.Core Drill Technique

Then there's the core drill, a hollow bit tipped with diamonds that spins to yank out a perfect cylinder. Sizes go from tiny for a single wire up to huge for full pipes. Concrete drilling companies love it for stuff like bathrooms or office wiring. Running water over it while drilling cools things down and cuts the dust, so you end up with a clean pull every time.Wire Sawing

For the beasts, like chopping up a thick foundation or bridge section, wire sawing steps up. Picture a tough wire loaded with diamonds looped around the concrete and tugged tight-it slices right through where bigger tools can't reach. It's a lifesaver on massive demos. No matter the pick, these ways all aim for clean work that doesn't rattle the whole site.

Tools That Power Concrete Cutting and Coring

Good tools make concrete cutting and coring go from headache to breeze, and concrete drilling companies know their kits inside out. Here's the lineup of what gets the job done right.- Diamond Core Drills: These bad boys use diamond tips to bore holes dead accurate, from quick home tweaks to factory-scale digs. Handhelds shine in cramped corners, while beefier rigs handle the deep stuff.

- Wall Saws: Locked on tracks for steady vertical work, they're pros at framing out big holes without wobbles.

- Flat Saws: For slicing across floors or roads, these run on gas or electric and keep things level.

- Ground Penetrating Radar (GPR): Before the blades spin, GPR sweeps for buried surprises like steel bars or pipes. It's all about dodging trouble without breaking ground.

- Windsor Probe Systems: When testing, the goal is to shoot a pin into gauge how strong the concrete really is-quick numbers that tell the full story.

Applications of Concrete Cutting and Coring

Concrete cutting and coring pop up everywhere in construction, making tweaks that keep projects rolling. Check out some spots where it shines:- Utility Installations: Drilling with a core drill opens paths for drains, power lines, or fiber optics in homes, shops, or plants-keeps everything flowing without a mess.

- Structural Testing: Pulling cores lets you check strength or soak levels, hitting marks like those in ASTM C42 for peace of mind.

- HVAC and Fire Systems: It carves routes for air vents, sprinklers, or heaters, blending new into old like it was always there.

- Renovation and Demolition: Want a new staircase or to bust out a slab? Cutting and coring handle the details safely.

- Bridge and Road Construction: Saws trim or repair big infrastructure, locking in long-haul toughness.

Why Precision and Safety Matter

In concrete cutting and coring, nailing the details isn't optional; it's everything. One slip could nick a steel rod, zap a wire, or throw the whole frame off, turning a simple job into a nightmare with fixes that cost a fortune or worse.

That's why scanning first with GPR is a must-it maps the hidden bits so your core drill stays clear. Safety's baked in too, with steps like:

In concrete cutting and coring, nailing the details isn't optional; it's everything. One slip could nick a steel rod, zap a wire, or throw the whole frame off, turning a simple job into a nightmare with fixes that cost a fortune or worse.

That's why scanning first with GPR is a must-it maps the hidden bits so your core drill stays clear. Safety's baked in too, with steps like:

- Proper Ventilation: Fans and water sprays chase away dust and smoke, especially on dry runs.

- Personal Protective Equipment (PPE): Goggles, hard hats, and noise gear keep crews sharp and safe.

- Regular Equipment Maintenance: Sharp blades and tight bolts mean fewer surprises.

- Trained Operators: Folks who know the ropes spot issues early and work smarter.

- When concrete drilling companies put this first, jobs wrap up smoothly, strongly, and on time.

Wrapping Up:

At the end of the day, concrete cutting and coring turn tough challenges into smart solutions. It's the quiet work that lets big ideas stand tall, from utility runs to strength checks on skyscrapers. With gear like diamond core drill rigs and smart scans, the pros make sure it's all safe, quick, and spotless.

Got a project that needs that kind of touch? Swing by Concrete Insight for a chat. We've got the know-how to make your build shine-hit us up for a no-strings quote and let's get started.

Comments